What type of humidity sensor you should choose?

Humidity is the presence of water in the air. This amount of water in the air or vapor can affect human comfort as well as many manufacturing processes. Consequently, monitoring and controlling humidity with humidity sensors is desirable in many situations – industrial, medical, agricultural and domestic situations. Humidity measurements can be stated in a variety of terms and units. The three commonly used terms are absolute humidity, relative humidity (RH) and dew point.

Relative vs. absolute humidity

Absolute humidity measures the exact physical amount of water in the air while Relative humidity compares how much water is in the air, compared to how much water could be in the air, or the maximum vapor pressure.

Absolute humidity

Absolute humidity is the actual amount of water vapor present in the air, regardless of the temperature. More precisely, the absolute humidity is the ratio of of the mass of water vapor to the volume of dry air or gas and it is largely determined by the nature of the surface under the air mass. It is expressed as grams of moisture per cubic meter of air (g/m3) and can be calculated from known RH, temperature, or measured directly. For example, if the water vapor in 1 cubic meter of air weighs 35 grams, the absolute humidity of the air is 35 g/m3.

Relative humidity

Relative humidity is defined as the ratio of the current amount of water vapor (absolute humidity) in the air to the maximum amount to be contained at the current air temperature. The capacity of air to hold water vapor is heavily dependent on its temperature. The warmer the air, the more moisture it can contain. If the moisture content in the air remains constant, the relative humidity decreases as the temperature increases or relative humidity increases as temperature decreases. When air can hold no more moisture at a given temperature (i.e. the RH is 100%), the air is said to be saturated.

Dew point

Dew point, expressed in °C, is the temperature and pressure at which a gas begins to condense into a liquid. When air cools to its dew point through contact with a surface that is colder than the air, water will condense on the surface. Devices called hygrometers are used to measure dew point over a wide range of temperatures. These devices consist of a polished metal mirror which is cooled as air is passed over it.

Key humidity expressions

| Term | Definition | Unit |

| Relative Humidity (RH) | How much water is in the air, compared to how much water could be in the air, or the maximum vapor pressure. Ratio of vapor pressure to saturation pressure. Relative humidity is a function of temperature and is a relative measurement. | % |

| Absolute Humidity (AH) | Actual amount of water vapor present in the air, regardless of the temperature, expressed as grams of moisture per cubic meter of air | g/m3 |

| Dew point | Temperature at which the water vapor in gas condenses to water. It is a function of pressure but independent of temperature and absolute humidity measurement. | °C |

Types of humidity sensors

A humidity sensor is an electronic device that measures the humidity in its environment and converts its findings into a corresponding electrical signal. Humidity sensors are among the most commonly used instruments in environmental monitoring applications. They vary widely in size and functionality; some can be found in handheld devices such as smartphones, while others are integrated into larger embedded systems such as air quality monitoring systems. Humidity sensors are commonly used in the meteorology, medical, automobile, HVAC and manufacturing industries.

Humidity sensors can be divided into three types as each type uses a different method to calculate humidity:

- Capacitive (Relative humidity)

- Resistive (Relative humidity)

- Thermal (Absolute humidity)

Capacitive humidity sensor

Approximately 75% of the humidity sensors on the market today are based on the capacitive technique. Capacitive humidity sensors offer several advantages, including very low power consumption and high output signals. They uses capacitive measurement, which relies on electrical capacitance.

The capacitive sensor is composed of two metal plates, or electrodes, separated by a thin layer of non-conductive polymer film. Capacitive sensors use these two electrodes to monitor the capacitance – the ability to store an electric charge of a thin metal strip placed between them. The film attracts moisture from the air and when the moisture contacts the metal plates it creates a voltage change. As the humidity in the air changes the polymer will absorb and release water vapor, which changes the electrical capacitance of the sensor The metal’s capacitance increases or decreases at a rate that is directly proportional to the change of humidity in the sensor’s environment. The output voltage measurement is captured and can be displayed via an analog output into another system or converted into a digital reading that indicates the amount of moisture in the air.

The capacitive type sensors are linear and can measure relative humidity from 0% to 100%. This type of sensor has proven to behave very predictably and reliably over the long term. That is why Capacitive relative humidity sensors are widely used in industrial, commercial, and weather telemetry applications.

One of the limitations of these sensors is their temperature dependence and capacitive sensors are limited by the distance the sensing element can be located from the signal conditioning circuitry.

Advantages of Capacitive Humidity Sensors

- The output voltage is near linear.

- They provide stable results over long usage.

- Can detect wide range of RH.

Disadvantages of Capacitive Humidity Sensors

- The distance from the sensor and signaling circuit is limited.

Resistive humidity sensor

Resistive sensors work on a similar principle to capacitive sensors, where electrical change is measured to produce a value for relative humidity. Although resistive sensors use a hygroscopic (moisture-absorbing) material like the capacitive system, the Resistive humidity sensors operate on a different principle. The difference is that the measurement is of the resistance change in the material rather than the capacitance. The transduction mechanism of resistive humidity sensors involves the changes in conductivity caused by the adsorption of water vapor. They measure the change in electrical impedance of a hygroscopic medium such as a conductive polymer, salt, or treated substrate.

The output voltage has an inverse exponential relationship to relative humidity. Modern Resistive Humidity Sensors are coated with ceramic substance to provide extra protection. The electrodes in the sensor are usually made of noble metals like gold, silver or platinum.

The benefit of a resistive sensor is the high surface-volume ratio, which allows it to measure humidity changes in the environment up to 90% relative humidity at room temperature. These systems do have limitations, and as such are not optimal for measuring values below 5% RH. The small size, low cost, interchangeability, and long-term stability make these resistive sensors suitable for use in control and display products for industrial, commercial, and residential applications.

Advantages of Resistive Humidity Sensors

- Low cost

- Small Size

- The distance between the sensor and signal circuit can be large that is why this sensor is suitable for remote operations

- Highly interchangeable as there are no calibration standards.

Disadvantages of Resistive Humidity Sensors

- Resistive Humidity Sensors are sensitive to chemical vapors and other contaminants

- The output readings may shift if used with water soluble products.

Thermal humidity sensor

Thermal Humidity Sensors are also known as Absolute Humidity (AH) Sensors as they measure the Absolute Humidity. They measure the thermal conductivity of both dry air as well as air with water vapor. The difference between the individual thermal conductivities can be related to absolute humidity.

Unlike relative sensors, thermal sensors utilize two probes, one is encased in a chamber filled with dry Nitrogen while the other is exposed to open environment through small venting holes. When the circuit is powered on, the resistance of the two probes are calculated and the difference between those two values is directly proportional to Absolute Humidity (AH).

Source: electronics hub

Advantages of Thermal Humidity Sensors

- Exceptionally durable

- Suitable for environments with high temperature and for high corrosive situations.

- Higher resolution compared to other types

Disadvantage of Thermal Humidity Sensors

- Exposure to any gas with thermal properties different than Nitrogen might affect reading measurement.

Which type of sensor to choose?

Choosing the best type of humidity sensing can be a complicated process. Capacitive sensors are considered to be more accurate and stable while producing repeatable results—however, their cost can be prohibitive, making them more suitable for medical type applications where precision is paramount. The less expensive resistive sensors are more practical for situations where frequent measurements are taken that do not require extremely precise data.

Nevertheless, the most important specifications that must be taken into consideration when selecting a Humidity Sensor are:

- Accuracy of the sensor.

- Repeatability of output

- Long-term stability

- Reliability of the sensor

- Calibration – requirements and methods

- Size of the sensor

- Interchangeability

- Cost effectiveness – Cost of the sensor and cost of replacement

- Circuit complexity

- Resistance to chemical and physical contaminants

- Ability to recover from condensation

For all these considerations to make sense, the prospective user needs an understanding of the most widely used types of humidity sensors and the general trend of their expected performance.

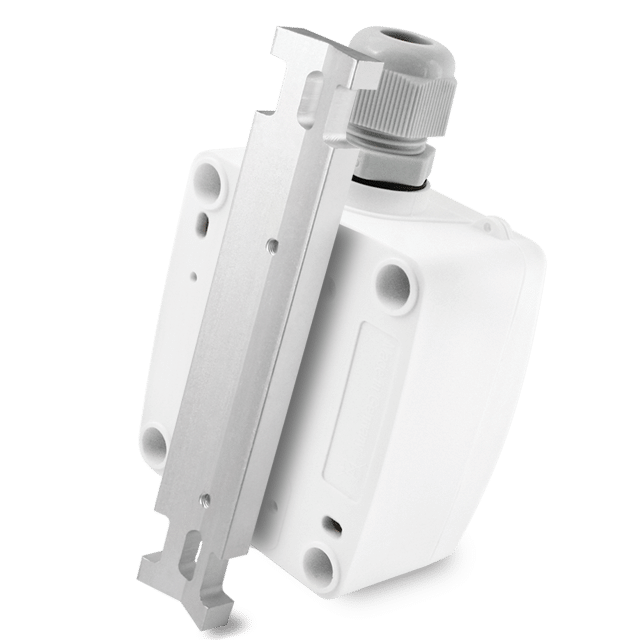

Andivi Humidity sensors

Andivi offers

working on a wide measuring range with the ability to display relative and absolute humidity as well as the dew point. Some of these sensors measure both humidity and temperature.

Using a DIP switch, 4 measuring ranges, relative humidity, absolute humidity, dew point, enthalpy, and mixing ratio can be modified.

The accuracy of humidity sensors in measuring humidity it is +/- 2% within the range of 20% – 80% of RH. All humidity sensors are produced in EU with 3-year guarantee on error-free operation and ensure high quality.

Digital humidity sensors

Please do not hesitate to contact us.